Description

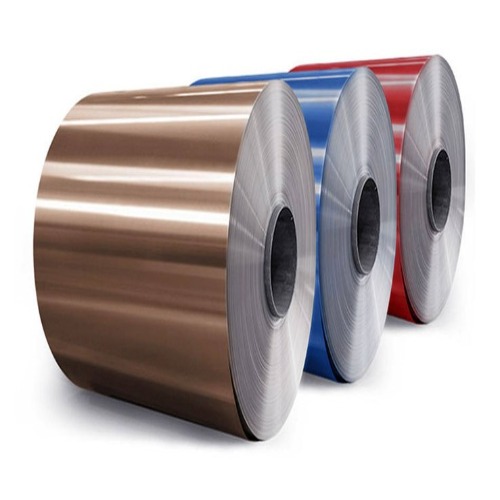

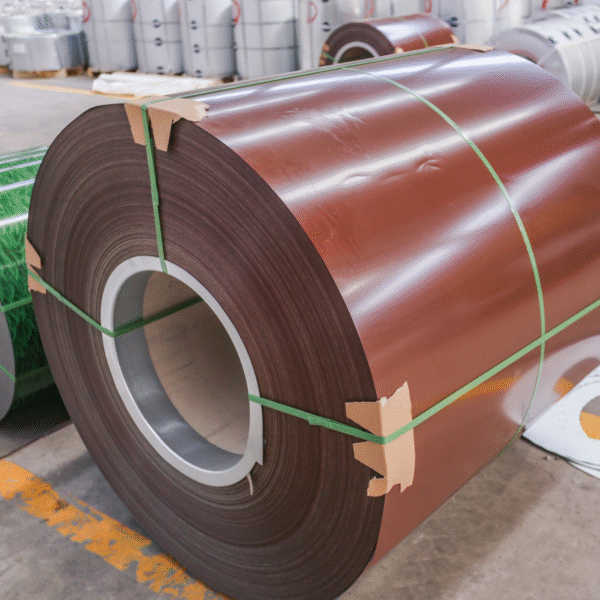

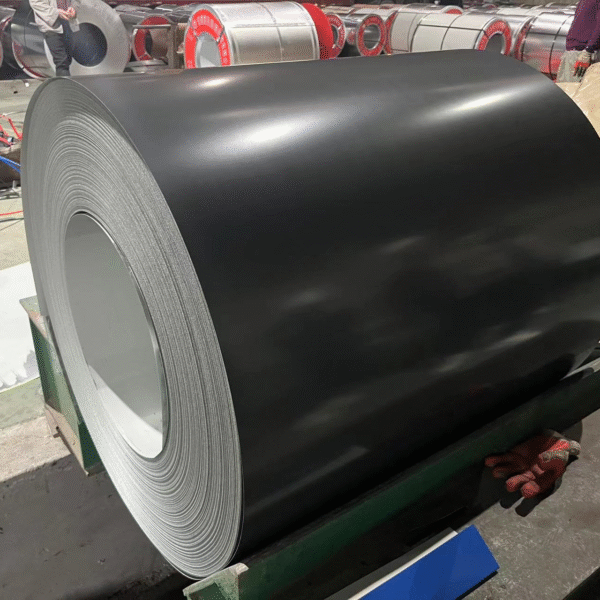

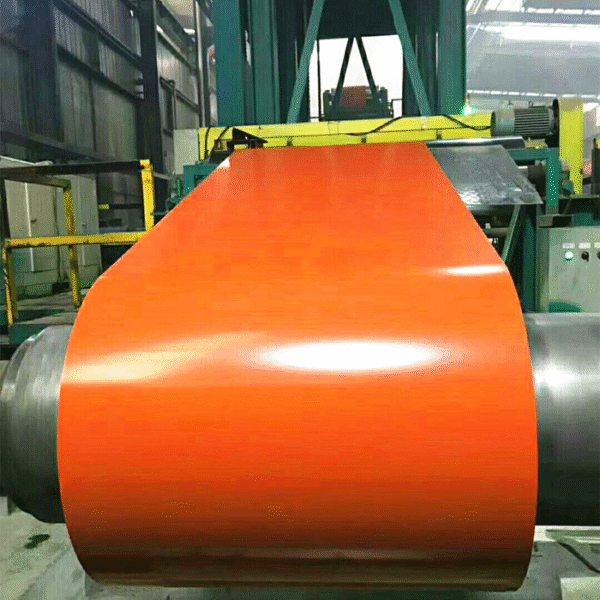

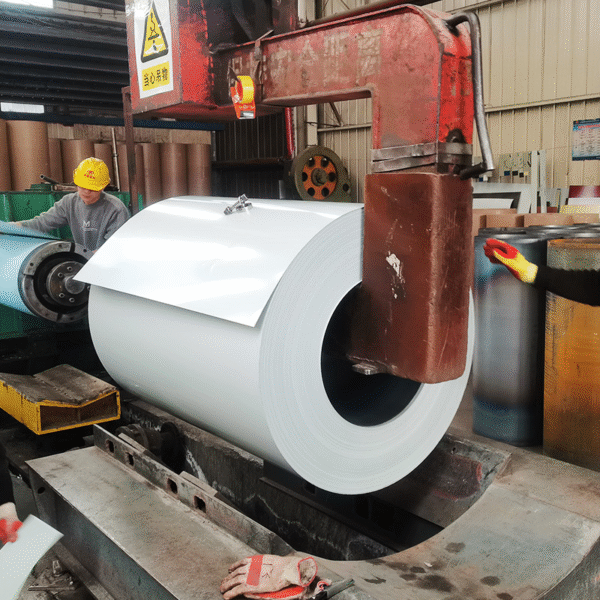

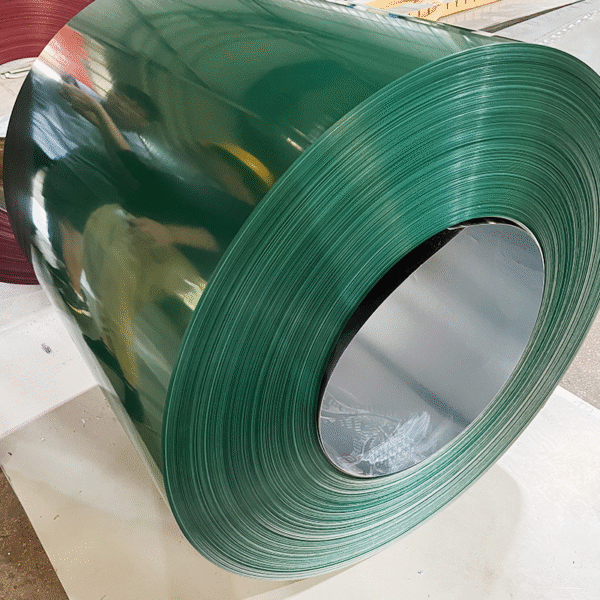

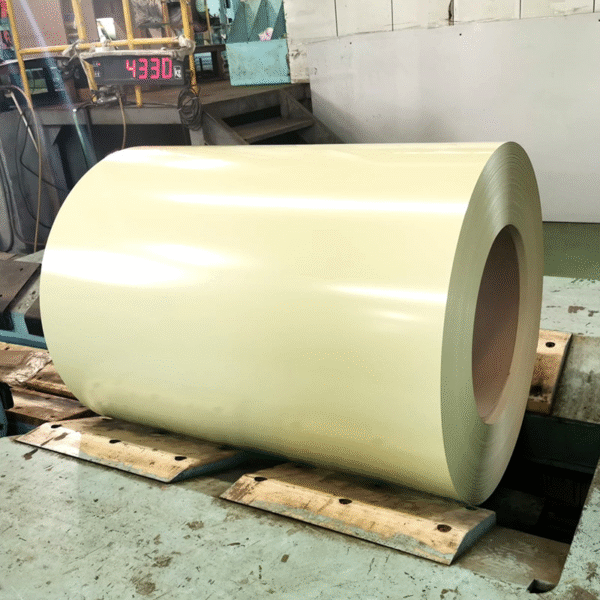

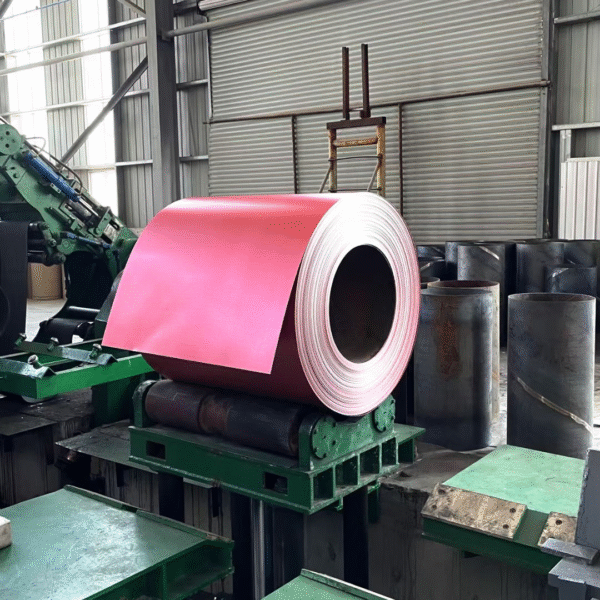

PPGI Coils (Pre-Painted Galvanized Iron Coils)

Base Material

-

Substrate: Hot-Dip Galvanized Steel (HDG)

-

Galvanization Layer: Typically zinc (Z) or zinc-aluminum alloy (Galvalume, AZ).

-

Purpose of Galvanization: Provides corrosion resistance by sacrificial protection — the zinc layer corrodes instead of the steel.

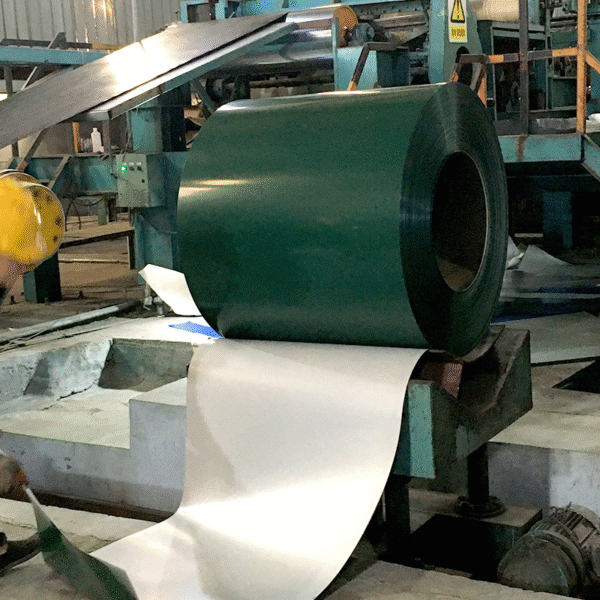

Coating Process

The process is usually done on a continuous coil coating line (CCL):

-

Surface Preparation: Cleaning, degreasing, and chemical pretreatment to ensure coating adhesion.

-

Primer Application: One or both sides are coated with a primer layer.

-

Topcoat Application: Using polyester, SMP (silicone-modified polyester), PVDF, polyurethane, or other specialized paints.

-

Baking & Cooling: Each coating layer is baked in an oven, then cooled.

-

Finishing: The coils are rewound and sometimes given a protective film for transport.

Common Coating Types

| Coating Type | Features | Typical Use |

|---|---|---|

| Polyester (PE) | Economical, good color range, moderate durability | Roofing, walls, and decorative panels |

| Silicone-Modified Polyester (SMP) | Better UV resistance, chalk resistance | Exterior building panels |

| Polyvinylidene Fluoride (PVDF) | Excellent weather, UV, and corrosion resistance | High-end architectural projects |

| High Durability Polyester (HDP) | Long life, good mechanical properties | Industrial roofing, coastal areas |

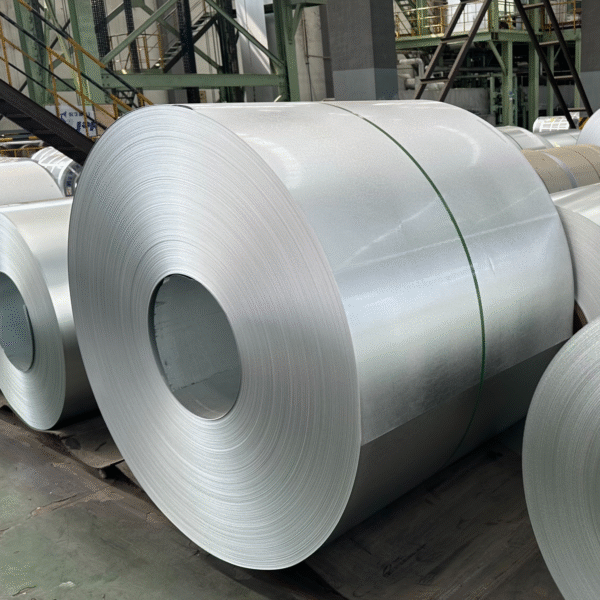

Typical Specifications

-

Thickness: 0.15 – 1.2 mm

-

Width: 600 – 1250 mm

-

Coating Thickness:

-

Zinc layer: 60–275 g/m² (per side, total both sides)

-

Paint layer: 5–20 μm (primer), 15–25 μm (topcoat)

-

-

Colors: RAL chart or custom

Advantages

-

Long service life due to combined zinc and paint protection.

-

Attractive finish — a wide range of colors and glosses.

-

Easy to transport and install.

-

Good formability for bending, pressing, or roll forming.

-

Environmentally friendly coatings are available.

Applications

-

Construction: Roofing sheets, wall panels, garage doors, and ceiling panels.

-

Home Appliances: Refrigerator backs, washing machine bodies, microwave oven panels.

-

Furniture: Cabinets, shelving.

-

Transport: Shipping containers, vehicle panels.

-

Industrial: Agricultural silos, cold storage rooms.

Why Choose ERAD Steel?

- Reliable quality and strong steel structure.

- Fast delivery and professional customer support.

- Trusted by clients across Africa, the EU, and the MENA region.

📲 Interested in our PPGI Coils ?

Chat directly with our team for pricing and details: