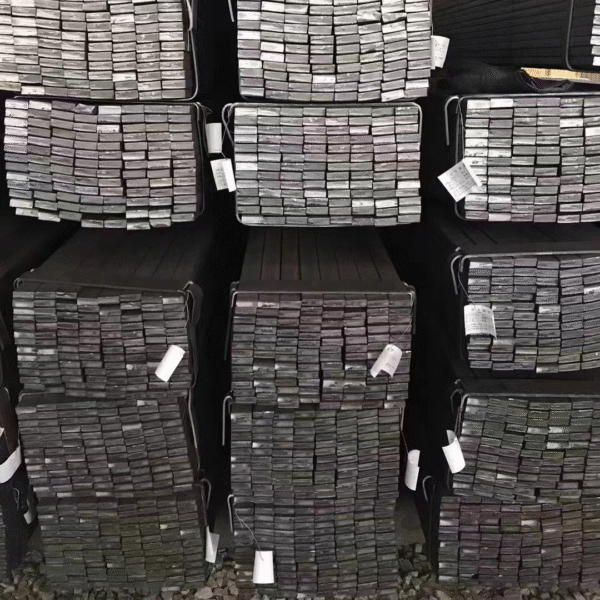

Description

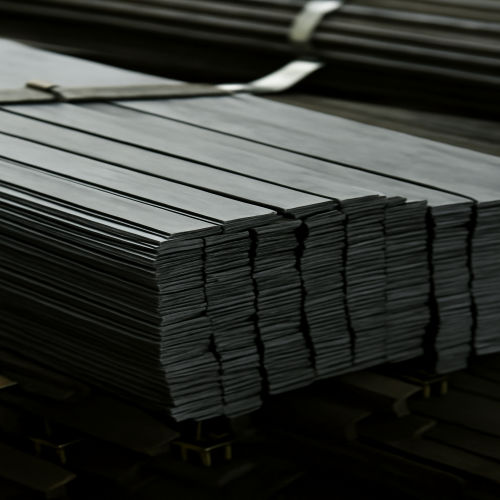

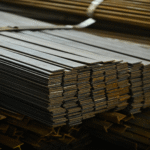

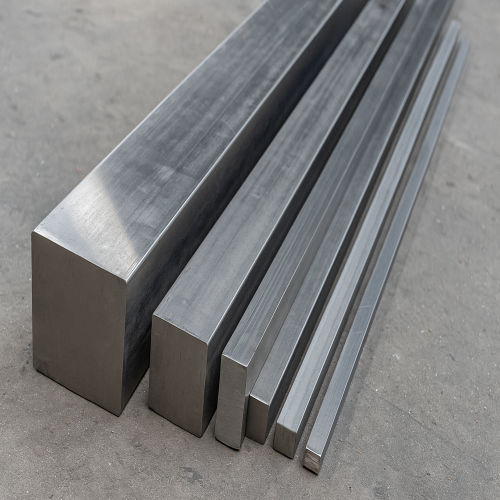

Plain Flat Bar

Base Material

-

Substrate: Carbon Steel, Alloy Steel (depending on application)

-

Shape: Rectangular cross-section

Properties:

-

Strength: Plain flat bars are known for their durability and strength, providing solid support in construction and automotive applications.

-

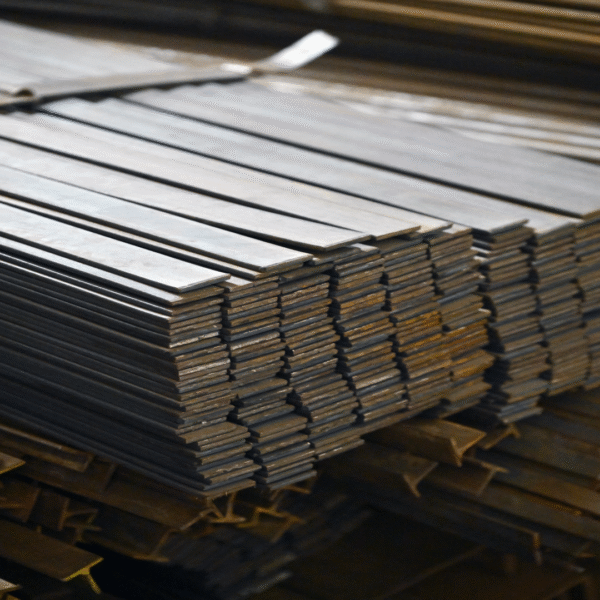

Surface Finish: Typically has a smooth, mill-finish surface, but can be polished or coated for specific uses.

-

Versatility: Can be used in a wide range of structural and industrial applications due to its simple rectangular shape, making it easy to weld, cut, or machine.

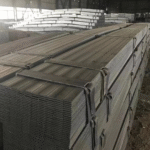

Manufacturing Process

-

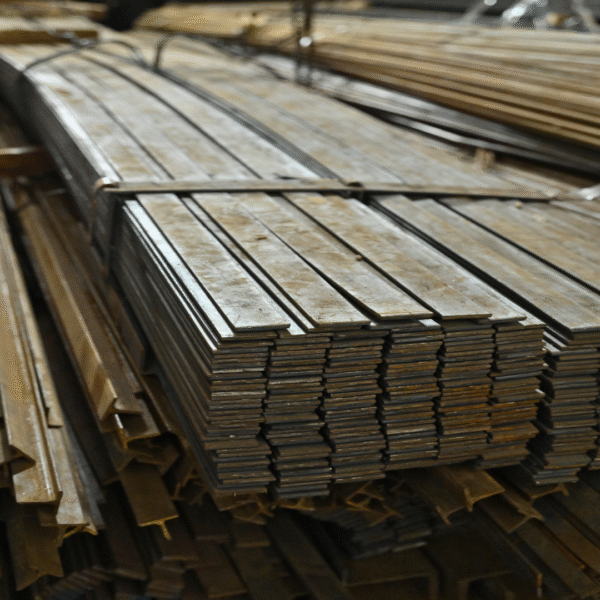

Heating: Steel billets are heated in a furnace to make them malleable for rolling.

-

Rolling: The heated billets are passed through rollers to form flat bars of various thicknesses and widths.

-

Cutting: The bars are then cut to the required length depending on customer specifications.

-

Finishing: The bars may undergo additional processes, such as coating or grinding, for specific applications (e.g., corrosion resistance or surface finish).

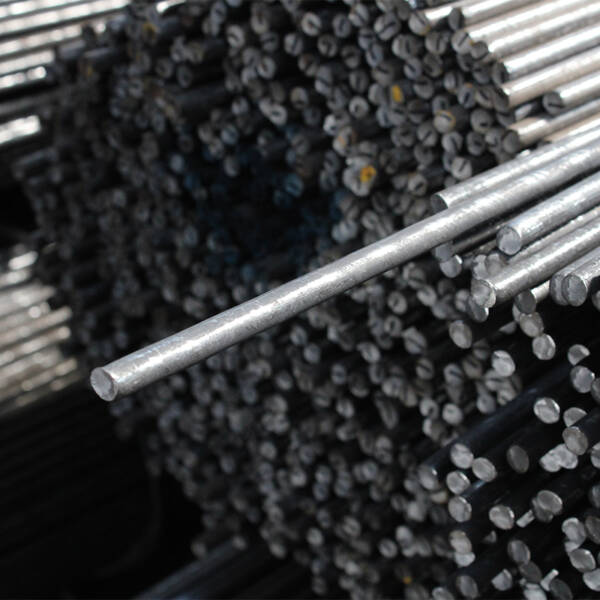

Common Grades of Plain Flat Bar

| Material | Features | Typical Use |

|---|---|---|

| Carbon Steel | Cost-effective, easy to weld and fabricate | Construction, structural frames, automotive components |

| Alloy Steel | High tensile strength and wear resistance | Heavy-duty industrial applications, machinery parts |

Typical Specifications

-

Thickness: Typically ranges from 3 mm to 50 mm (custom sizes available on demand).

-

Width: Varies, typically from 20 mm to 200 mm, based on specific application needs.

-

Length: Standard lengths range from 3 meters to 6 meters, but custom lengths can be provided.

-

Surface Finish: Standard mill finish, but options for polished or coated surfaces are available.

Advantages

-

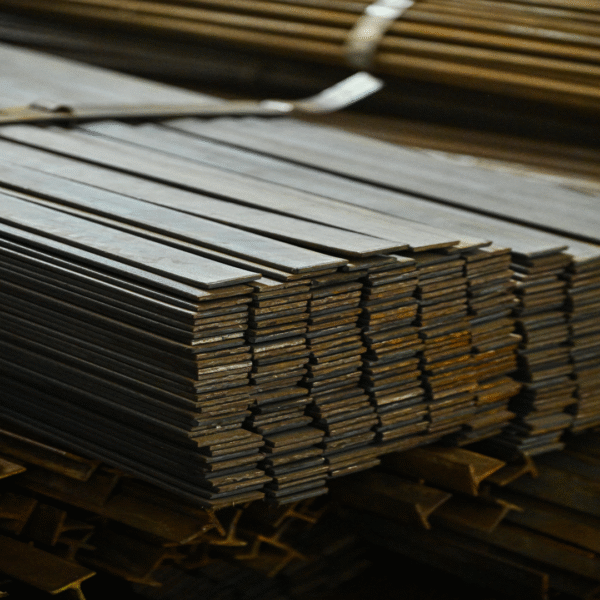

High Strength: Provides excellent load-bearing capacity, ideal for structural applications in buildings and industries.

-

Versatility: Can be used for a wide variety of applications, including construction, automotive, and machinery manufacturing.

-

Ease of Fabrication: Flat bars are easy to weld, cut, and machine, providing flexibility in custom applications.

-

Cost-Effective: Flat bars are generally affordable, making them a popular choice for structural and industrial purposes.

Applications

-

Construction: Used as beams, braces, frames, and supports in buildings and infrastructure projects.

-

Automotive: Used in the manufacture of various automotive components, such as chassis parts and structural elements.

-

Industrial Manufacturing: Used in the production of machinery, equipment, and structural components.

-

Furniture: Can be used in furniture manufacturing, including shelving units and supports.

-

Structural Engineering: Often used as reinforcements or in the fabrication of metal structures.

Why Choose ERAD Steel?

- Reliable quality and strong steel structure.

- Fast delivery and professional customer support.

- Trusted by clients across Africa, the EU, and the MENA region.

📲 Interested in our Plain Flat Bar?

Chat directly with our team for pricing and details: