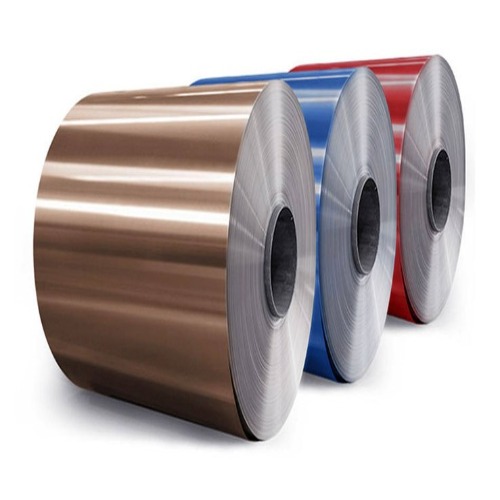

Description

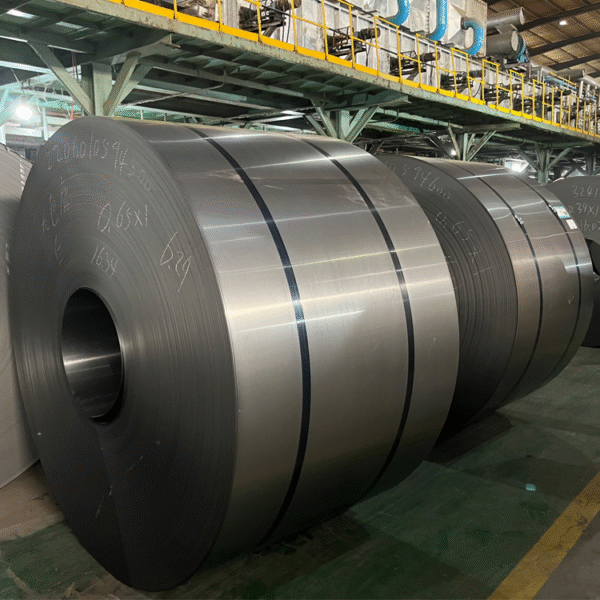

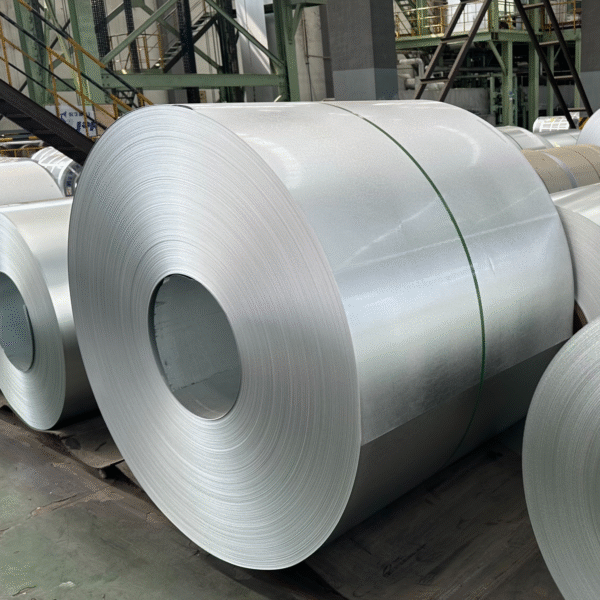

Hot Rolled Coils

Erad Steel’s hot-rolled coils are renowned for their exceptional formability, weldability, and strength, making them a preferred choice for structural components, fabrication, and construction projects. They serve as the base material for many further-processed steel products, including cold-rolled coils, galvanized sheets, and structural steel profiles.

Product Overview

-

Material: Low carbon steel, alloy steel, or structural steel grades.

-

Production Process: Rolled at high temperatures (above 1,700°F / 927°C).

-

Custom Options: Width, thickness, and coil weight can be tailored to your specific needs.

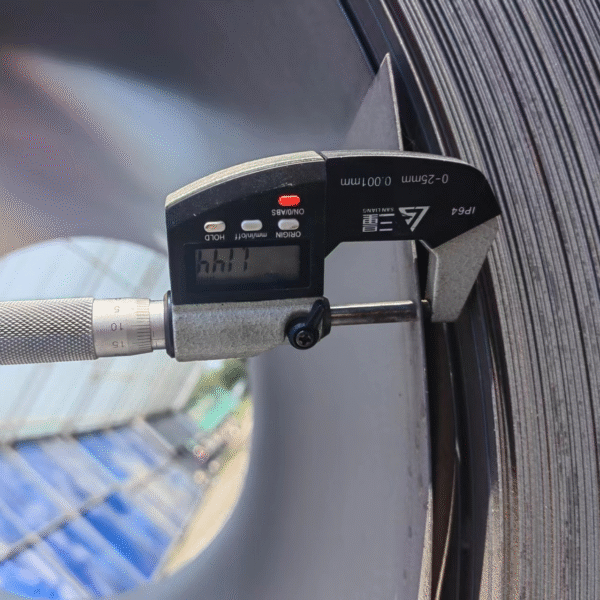

Hot Rolled Coil Specifications

| Specification | Details |

|---|---|

| Product Thickness | Typically 1.2 mm to 25 mm |

| Product Width | 600 mm to 2,000 mm |

| Coil Weight | Up to 25 metric tons |

| Steel Grade | Common grades include S235JR, S275JR |

| Surface Condition | Mill finish, scale-covered |

| Standards | As per EN, ASTM, or JIS standards |

| Edge Condition | Mill edge or trimmed edge |

| Available Forms | Coils, sheets, or plates |

| Delivery Condition | As-rolled or pickled and oiled |

Key Features

-

High strength and durability

-

Good weldability and machinability

-

Cost-effective for large-scale manufacturing

-

Wide range of sizes and grades available

-

Base material for cold rolling and galvanizing

Applications

-

Structural beams, channels, and angles

-

Automotive frames and parts

-

Shipbuilding and bridge construction

-

General fabrication and heavy machinery

-

Storage tanks and containers

-

Base material for cold-rolled coils

Optional Add-ons

-

Pickled and Oiled (P&O) finish for improved surface quality

-

Edge trimming for precise width control

-

Custom packaging for export

Why Choose ERAD Steel?

- Reliable quality and strong steel structure.

- Fast delivery and professional customer support.

- Trusted by clients across Africa, the EU, and the MENA region.

📲 Interested in our Hot Rolled Coils ?

Chat directly with our team for pricing and details: