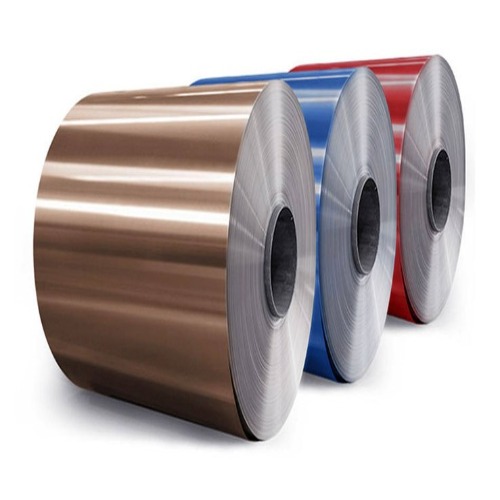

Description

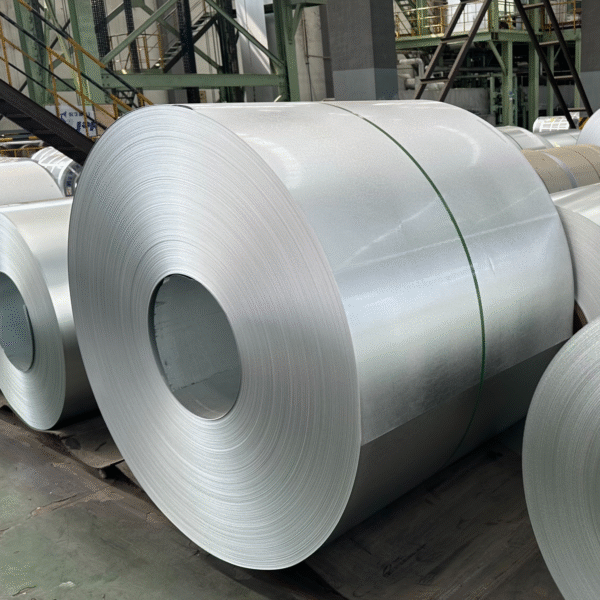

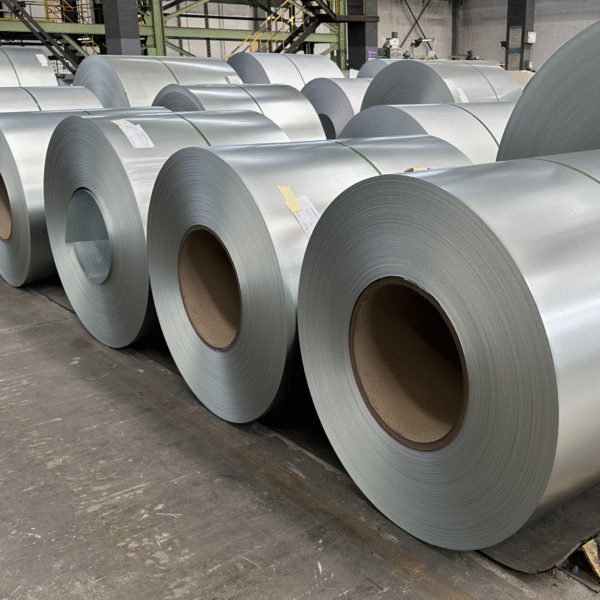

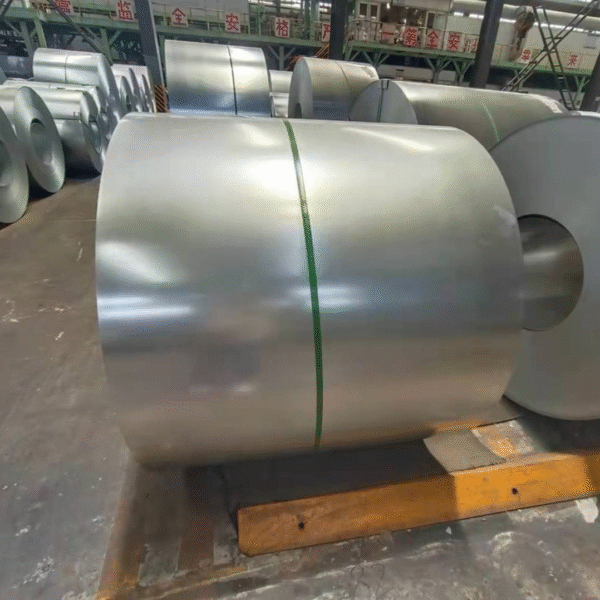

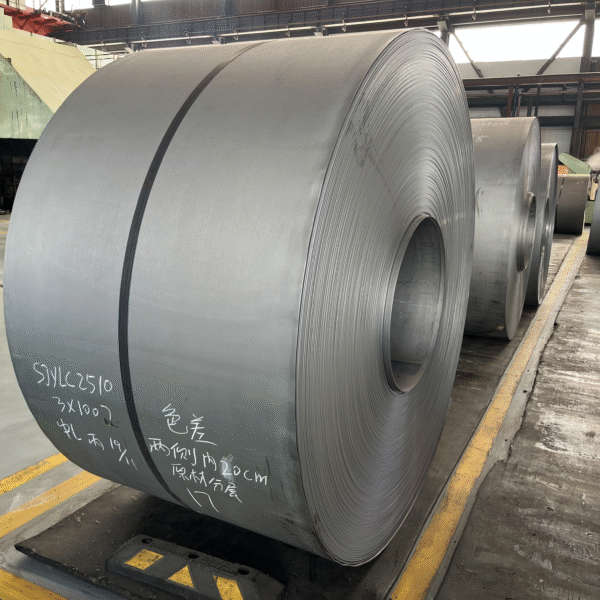

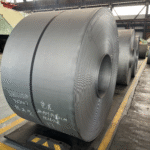

Cold Rolled Coils

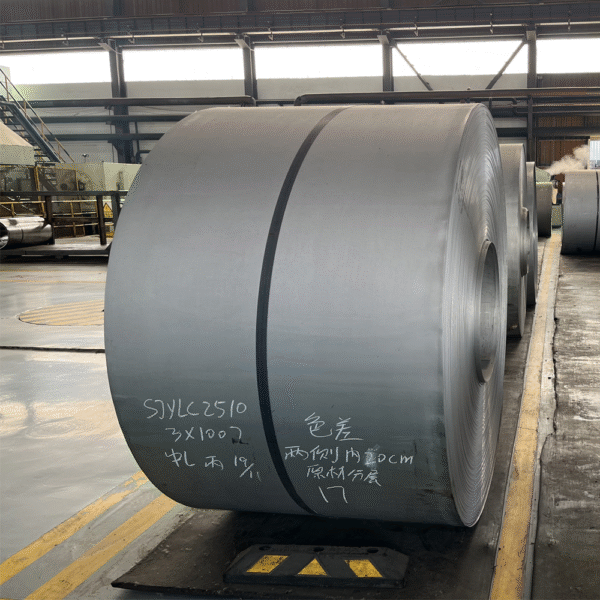

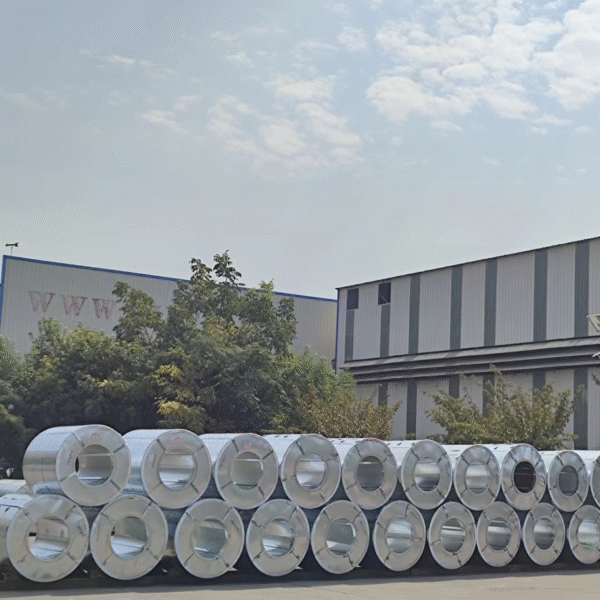

Erad Steel’s Cold Rolled Coils are high-quality steel that have undergone an additional cold rolling process after hot rolling. This process reduces the thickness of the steel and allows it to cool naturally at room temperature, resulting in a product with exceptional surface finish, high tensile strength, and precise dimensional tolerances.

Cold-rolled coils are ideal for applications that require excellent formability, superior strength, and a smooth surface for further finishing processes such as painting, coating, or galvanizing. They are widely used in manufacturing, construction, automotive, and appliance production.

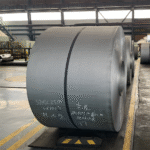

Cold Rolled Coil Specifications

| Specification | Details |

|---|---|

| Product Thickness | 0.25 mm up to 3 mm |

| Coil Width | 600 mm to 1500 mm |

| Coil Inner Diameter | 508 mm / 610 mm |

| Steel Grade | SPCC, SPCD, SPCE, or as per customer requirements |

| Tensile Strength | 270–410 MPa |

| Surface Finish | Bright, matte, or custom finish |

| Available Coatings | Oiled or unoiled |

| Packaging | Standard export packing with steel strapping and edge protection |

| Standards | ASTM, JIS, EN, or as specified |

Product Overview :

-

Materials: Premium-grade carbon steel processed through cold rolling.

-

Thickness Range: 0.25 mm to 3 mm.

-

Width Range: 600 mm to 1500 mm.

-

Applications: Suitable for deep drawing, bending, and precision forming operations.

-

Surface Options: Bright or matte, with optional oiling for corrosion prevention.

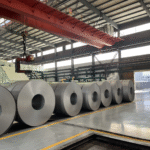

Key Features:

-

Superior dimensional accuracy and flatness.

-

High tensile strength with low flexibility, ideal for structural and industrial use.

-

Smooth surface finish suitable for painting and coating.

-

Consistent mechanical properties across the coil.

-

Available in various grades to meet industry-specific needs.

Applications:

-

Automotive body panels and parts.

-

Electrical appliances and casings.

-

Furniture and shelving systems.

-

Metal containers and packaging.

-

Construction components and interior finishing.

Optional Add-ons:

-

Custom coil widths and weights.

-

Protective film lamination for surface protection.

-

Edge trimming and slitting services.

Why Choose ERAD Steel?

- Reliable quality and strong steel structure.

- Fast delivery and professional customer support.

- Trusted by clients across Africa, the EU, and the MENA region.

📲 Interested in our Cold Rolled Coils ?

Chat directly with our team for pricing and details: