Description

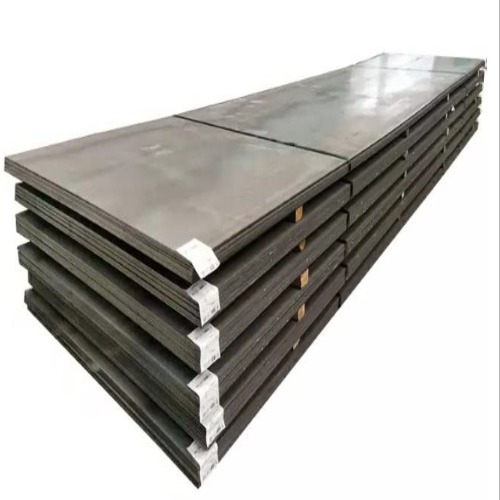

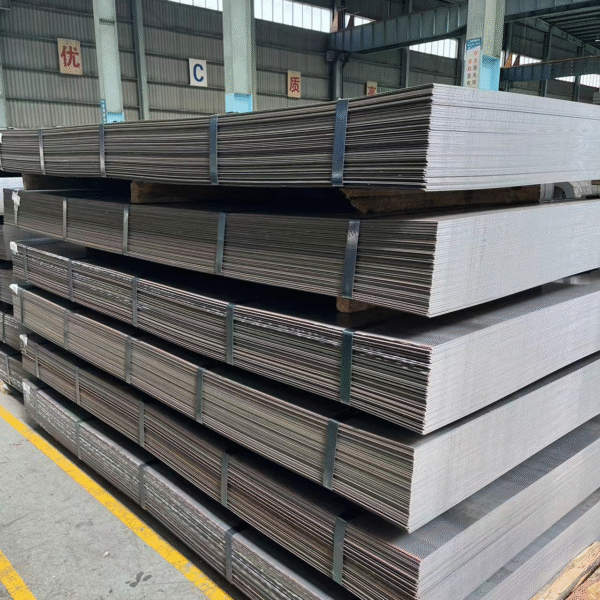

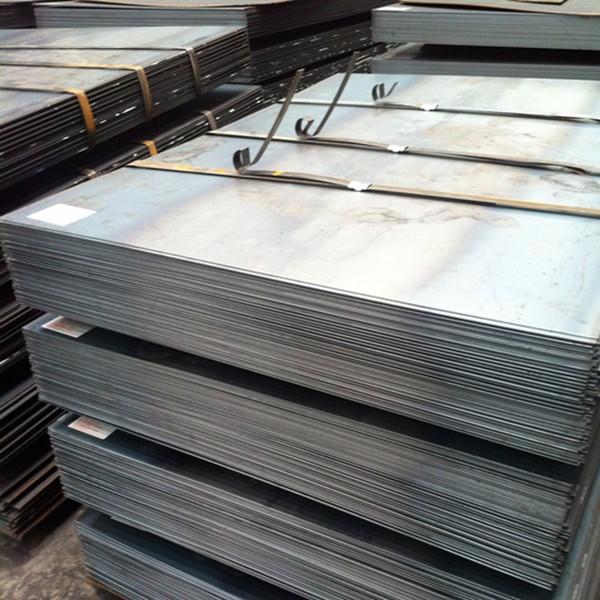

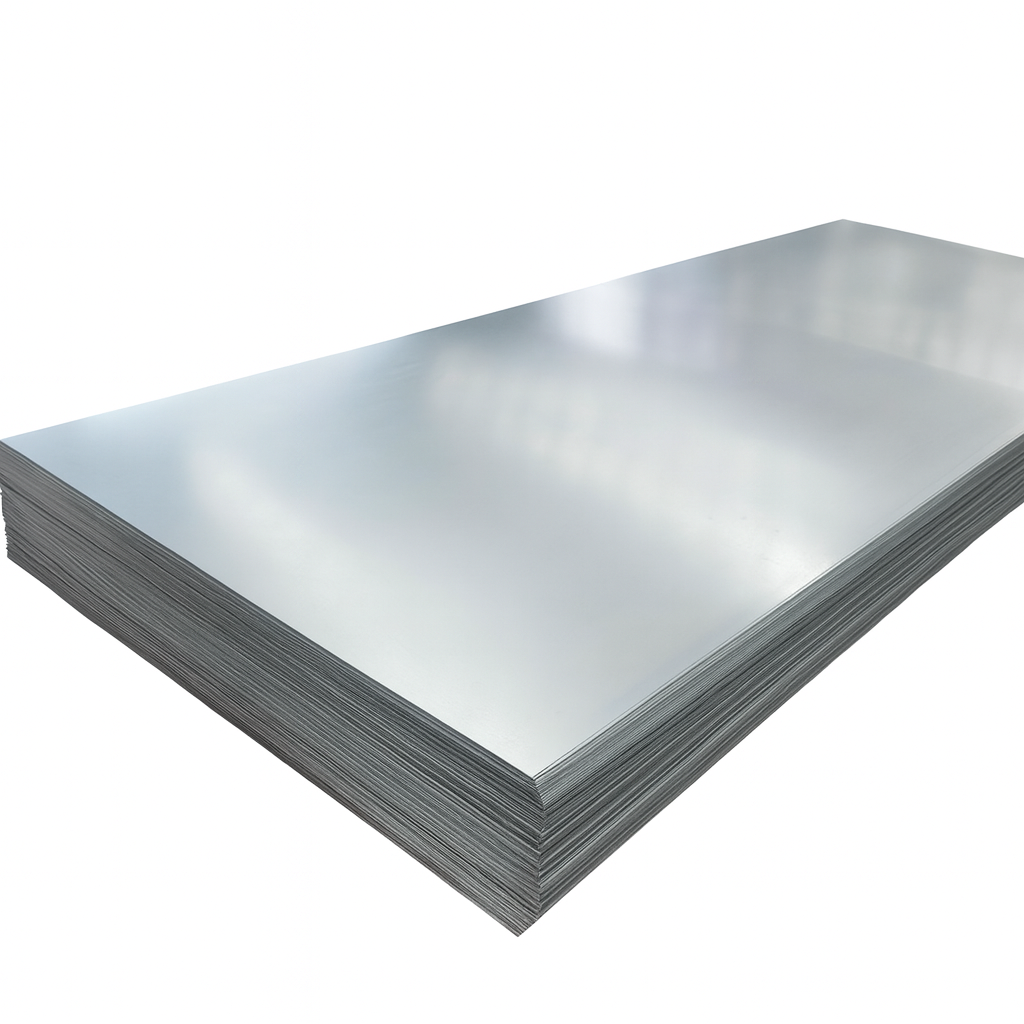

Hot Rolled Plate (Carbon Steel Plates)

Base Material

-

Substrate: Carbon Steel

-

Plate Type: Hot Rolled Carbon Steel Plate

Properties:

-

Strength: Hot-rolled plates are known for their strength, making them suitable for structural applications.

-

Manufacturing Process: Easier to manufacture than cold-rolled plates, with lower production costs.

-

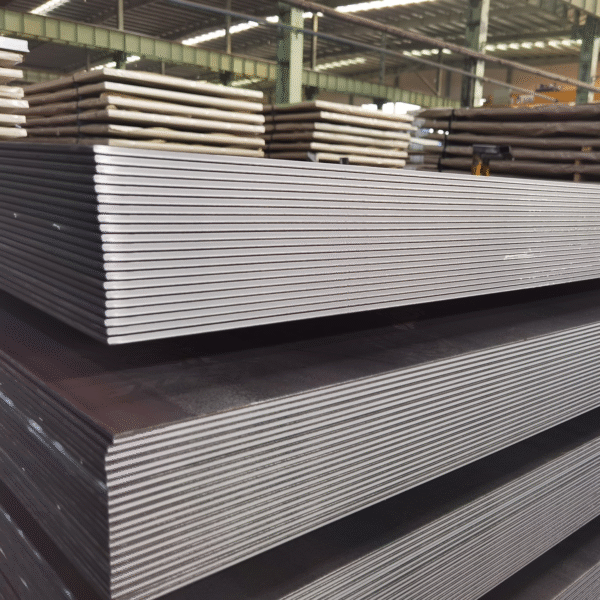

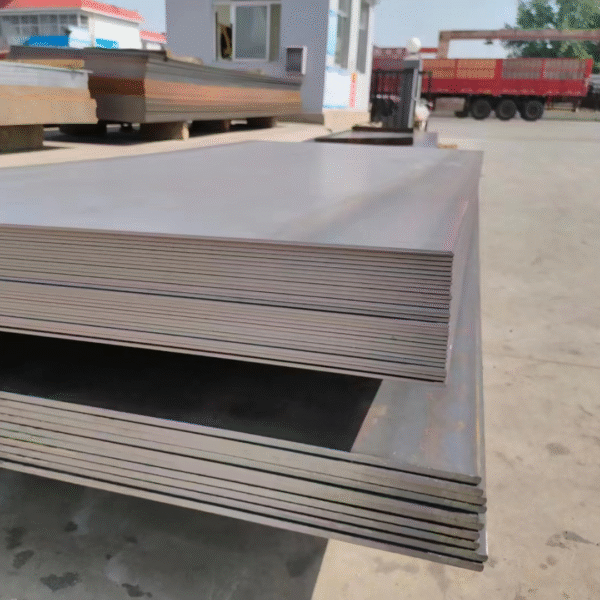

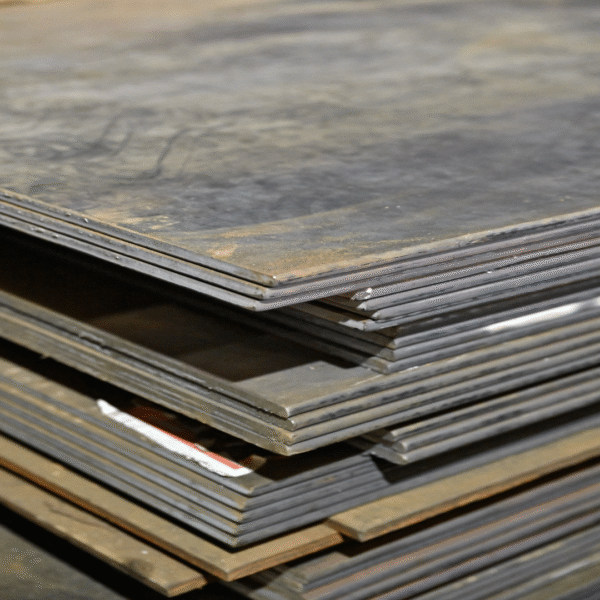

Finish: Typically has a rough, scale-like surface due to the cooling process.

Manufacturing Process

-

Heating: The steel is heated to a temperature above its recrystallisation point.

-

Rolling: The heated steel is passed through rollers to achieve the desired thickness and shape.

-

Cooling: The plate is allowed to cool, either in air or through water quenching.

-

Cutting: After cooling, the plate is cut into the desired length and width.

-

Finishing: The edges may be deburred, and some plates may undergo surface treatments to improve the finish.

Typical Specifications

-

Thickness: 3.0 – 100 mm (depending on grade and application)

-

Width: 1000 – 2500 mm (standard range)

-

Length: Up to 12 meters (depending on customer requirements)

- Grade: ST37 – ST44

Advantages

-

Cost-Effective: Lower production costs compared to cold-rolled plates.

-

Strength: High strength to support structural applications.

-

Versatility: Widely used across different industries due to its reliability.

-

Durability: Resistant to wear and tear, especially in high-impact and high-stress environments.

Applications

-

Construction: Bridges, ships, commercial buildings, municipal infrastructure.

-

Structural Engineering: Brackets, supports, beams, and columns.

-

Manufacturing: Heavy-duty machinery, pressure vessels, tanks, and structural frameworks.

-

Automotive and Transport: Vehicle chassis, body panels, and frames.

Why Choose ERAD Steel?

- Reliable quality and strong steel structure.

- Fast delivery and professional customer support.

- Trusted by clients across Africa, the EU, and the MENA region.

📲 Interested in our Hot Rolled Plate?

Chat directly with our team for pricing and details: